Effectiveness of Ceramic Ultrafiltration Membrane for Seawater Desalination Pre-treatment

Effectiveness of Ceramic Ultrafiltration Membrane for Seawater Desalination Pre-treatment

Nanostone Water’s ceramic desalination pretreatment system removes harmful algal blooms, suspended solids and high levels of dissolved organics from seawater with high reliability, enabling RO desalination systems to operate to rated capacity and planned costs over an extended life. Our single-step solution also eliminates multiple pretreatment processes, reducing capital expense and footprint.

Download PDFEffectiveness of Ceramic Ultrafiltration Membrane for Seawater Desalination Pre-treatment

Reverse osmosis (RO), the state-of-the-art technology for seawater desalination, performs well over extended periods so long as the feedwater is largely free of suspended solids and low in dissolved organics. However, existing pre-treatment technologies supplying RO systems struggle when exposed to high levels of dissolved organics, harmful algae blooms, and other sudden and variable influxes of suspended solids. When this material passes the pre-treatment system RO fouling increases drastically, reducing plant capacity, increasing cleaning cycles and chemical consumption and causing premature RO membrane failure.

For developers, owners and operators, these problems result in:

• Reduced plant utilization, which severely impacts plant economics;

• Elevated risks of operational disruptions; and

• Higher treatment costs

The desalination plants in Singapore are in some cases experiencing problems with the pre-treatment when polymeric membranes are applied leading to capacity issues. They’ve been experiencing the challenges that

• Unreliable SWRO pretreatment necessitating multiple pre-treatment steps (DAF, DMF, Polymeric UF)

• Variable seawater quality causing plant shutdowns

• Inadequate pretreatment requiring frequent SWRO cleans

• Expensive combination of processes

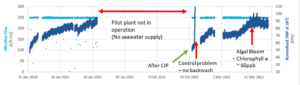

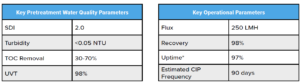

Nanostone Water has conducted the pilot in TUAS testbedding facility with its ceramic ultrafiltration membrane, and operated through algal blooms with no change to operational parameters or water quality.

Download the full PDF case study for more information.