Nanostone CM-151 Ceramic Ultrafiltration Membrane Enhances Lithium Extraction in China’s Salt Lakes

Nanostone CM-151 Ceramic Ultrafiltration Membrane Enhances Lithium Extraction in China’s Salt Lakes

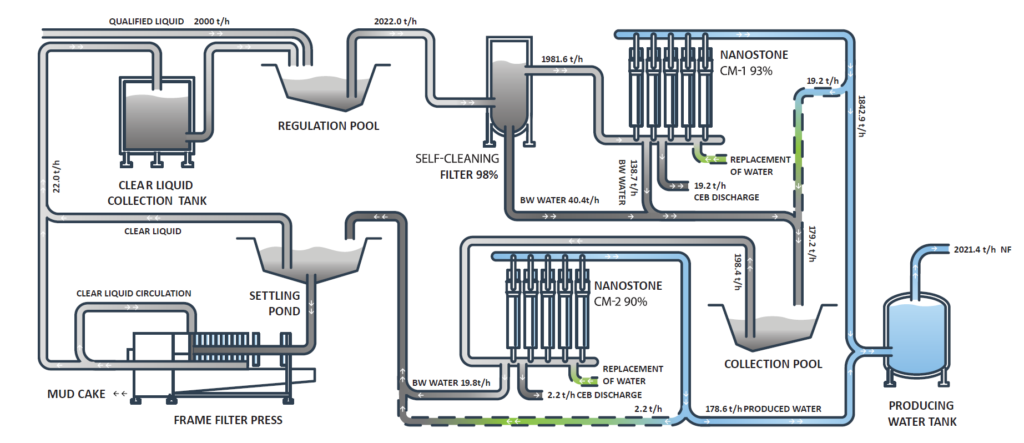

Data from Qinghai Salt Lake Lanke Lithium Industry Co. demonstrates that Nanostone’s CM-151 ceramic ultrafiltration membrane system ensures the long-term stability and success of the treatment process.

Download PDFMembrane separation technology is one of the best ways to extract lithium from salt lakes in China. Although there are substantial lithium resources in the salt-lake brine, the high ratio of magnesium to lithium and significant levels of impurities have resulted in low lithium content grade and yields.

Membrane separation technology from Nanostone can address these challenges by providing a range of benefits including:

- Excellent magnesium-lithium separation

- High recovery rates

- A shorter production cycle

- Reduced environmental protection expenditures

Qinghai Salt Lake Lanke Lithium Industry Co., Ltd., located in the Qaidam Circular Economy Development Zone, Qinghai, China, was faced with a number of challenges:

- There were suspended solids in the intermediate liquid system (SS≤100ppm), which greatly affected the lithium extraction process.

- The amount of suspended solids fluctuated greatly, which made pretreatment of the nanofiltration system difficult.

- Due to the high salt content of the intermediate liquid and the location of the site in the alpine area of northwest China, the nanofiltration membrane pretreatment system sometimes had to operate in extremely cold conditions, creating more challenges for the operation.

SOLUTION

Using Nanostone CM-151 ceramic ultrafiltration membrane as a pretreatment method for the nanofiltration membrane led to the following benefits:

- The system was able to withstand severe water quality fluctuations and temperature changes. This allowed it to maintain stable processing capacity and output levels even when water inflows were close to zero degrees.

- Excellent filtration efficiency, which enabled the plant to capture and remove high concentrations of suspended solids, ensure water quality, and protect downstream nanofiltration membranes.

- A robust ceramic material that can withstand high Total Dissolved Solids (TDS) influent without fiber breakage.

- Excellent cleaning and recovery performance to ensure stable and continuous operation of the system and maintain production schedules.

- Easy operation and maintenance, which decreased the frequency of cleanings and reduced chemical and water usage.

- High operating flux and a large active membrane area resulted in highly integrated, compact equipment with a small footprint, making it possible to increase future production capacity, even with limited space.

- The quality guarantee and longer lifecycle provided an excellent return for the Build-Operate-Transfer (BOT) projects.

Download the case study to discover how Nanostone Water ceramic technology help to solve the problems: Nanostone CM-151 Ceramic Ultrafiltration Membrane Enhances Lithium Extraction in China’s Salt Lakes